A mold for a dates container would likely be designed to create a specific shape and size of container suitable for packaging dates. Dates Container Mould Manufacturers focus on quality and durability depending on the material used for the containers (such as plastic, glass, or metal), the mold would be tailored to the manufacturing process involved.

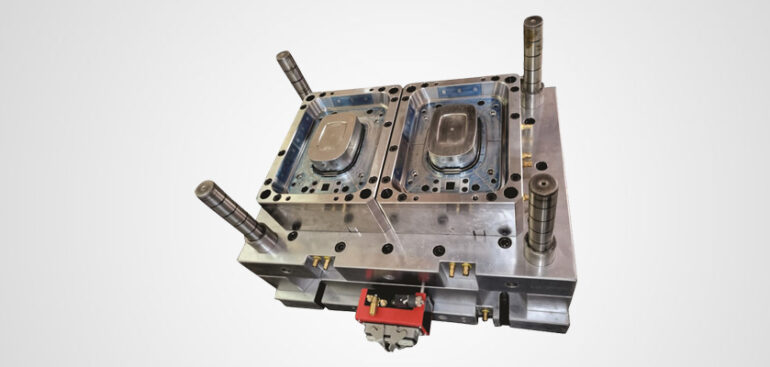

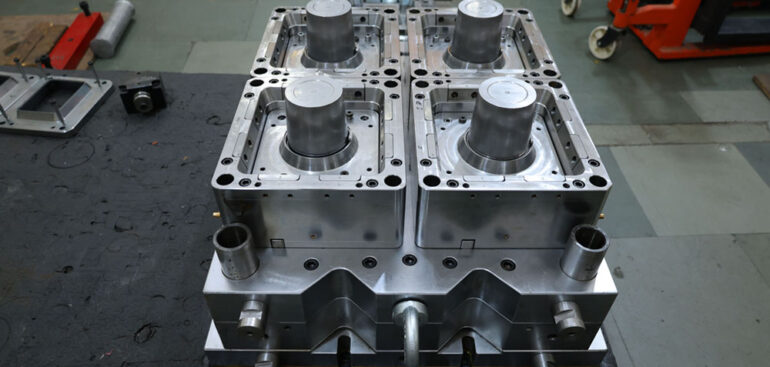

For plastic containers, injection molding is a common method. The mold would have a cavity in the shape of the desired container, and molten plastic would be injected into this cavity under high pressure. Once the plastic cools and solidifies, the mold opens, and the finished container is ejected.

For glass containers, molds are used in processes like blow molding or glass forming. In blow molding, a glass gob is placed into the mold cavity, then air is blown into the gob, forcing it to expand and take the shape of the mold. In forming processes, glass sheets or preforms are heated and shaped using the mold.

For metal containers, processes like metal stamping or deep drawing are common. In metal stamping, a flat sheet of metal is pressed into the shape of the mold cavity. Dates Container Mould Manufacturers work in deep drawing, a metal blank is drawn into the mold cavity to create the container shape.

In any case, the mold for a dates container would need to be carefully designed to ensure that the containers produced are of the desired size, shape, and quality. It would also need to be durable enough to withstand the rigors of repeated use in the manufacturing process.