Designing a mold for disposable food containers involves several considerations such as the material used, the design of the container, the production method, and the required volume of production.

Material Selection: Choose a suitable material for the mold. Common options include steel and aluminum. Aluminum is often preferred for its lighter weight and faster heat transfer properties, while steel molds are more durable and suitable for high-volume production.

Container Design: Decide on the design of the disposable food container. Consider factors such as size, shape, compartments (if any), and any specific features required for the intended use (e.g., lids, sealing mechanisms).

Mold Design: Design the mold based on the chosen material and container design. This involves CAD (Computer-Aided Design) software to create detailed 2D and 3D designs of the mold.

Manufacturing Process: Determine the manufacturing process for the mold. Common methods include CNC machining, EDM (Electrical Discharge Machining), and casting. CNC machining is often used for precision molds, while casting can be more cost-effective for larger molds.

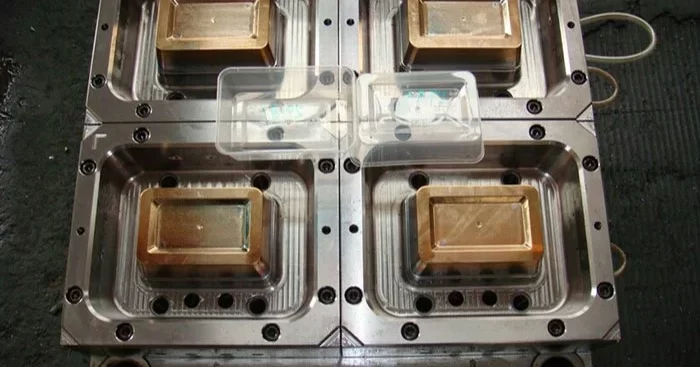

Mold Components: Identify the components of the mold, such as the core, cavity, ejector pins, cooling channels, and any slides or lifters needed for complex features.

Tooling: Once the mold design is finalized, tooling is created based on the design specifications. This involves precise machining and assembly of the mold components.

Testing and Optimization: Test the mold with sample materials to ensure that it produces containers to the desired specifications. Make any necessary adjustments or optimizations to improve the production process and quality of the containers.

Production: Once the mold is finalized and tested, it can be used for mass production of disposable food containers. The production process may involve injection molding, thermoforming, or other suitable methods depending on the material and design of the containers.

Maintenance: Regular maintenance of the mold is essential to ensure its longevity and consistent performance. This may include cleaning, lubrication, and periodic inspection for wear and damage.

Quality Control: Implement quality control measures throughout the production process to ensure that the containers meet safety and quality standards.

It’s important to note that designing a mold for disposable food containers requires expertise in mold design and manufacturing processes. Working with experienced professionals or consulting with mold manufacturers can help ensure a successful outcome. Additionally, factors such as regulatory requirements and sustainability considerations should also be taken into account during the design and production process.

A container mold for biryani would be designed specifically to create containers suitable for packaging biryani, a popular South Asian dish. Biryani Container Mould Manufacturers work on these containers are typically designed to hold a single serving of biryani and are often made of materials such as plastic, aluminum, or biodegradable materials.

Similar to molds for other types of containers, a mold for biryani containers would be customized to the desired shape, size, and material of the container. Injection molding is a common method for creating plastic containers, where molten plastic is injected into a mold cavity under high pressure and then cooled to solidify into the desired shape.

For aluminum containers, processes like metal stamping or deep drawing may be used. Metal stamping involves pressing a flat sheet of aluminum into the shape of the mold cavity, while deep drawing involves drawing a metal blank into the mold cavity to create the container shape.

In the case of biodegradable materials, molds may be used in processes such as compression molding or thermoforming, where the material is heated and formed into the shape of the mold cavity.

Biryani Container Mould Manufacturers use regardless of the material and manufacturing process used, the mold for biryani containers would need to be designed with considerations for the dimensions of the container, its structural integrity, and any features required for sealing or stacking the containers efficiently.