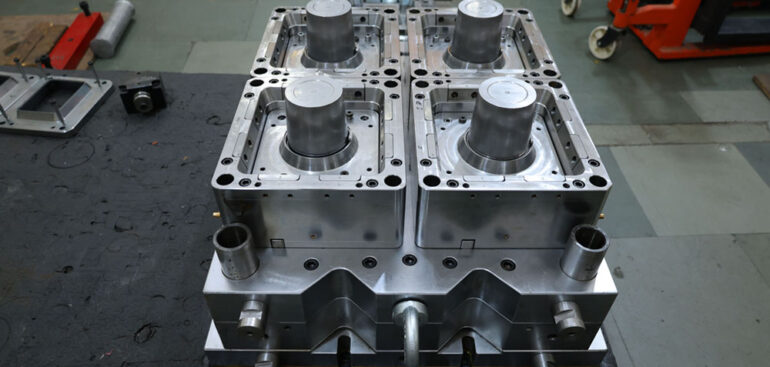

A food container mould is a specialized type of mould designed for the manufacturing of containers specifically intended for food storage or packaging. Food Container Mould Manufacturers can be made these containers from various materials, including plastic, glass, or metal, depending on the specific requirements of the application. Here are some key aspects related to food container moulds:

Material Selection:

- Plastic Molds: Common materials for plastic food container moulds include high-density polyethylene (HDPE), polypropylene (PP), polyethylene terephthalate (PET), and others. These materials are chosen for their food-grade characteristics, durability, and suitability for various moulding processes.

- Glass Molds: For glass food containers, moulds are typically made from cast iron or steel. Glass moulds must be able to withstand high temperatures during the glass forming process.

Moulding Techniques:

- Injection Moulding: Common for plastic food containers, injection moulding involves injecting molten plastic into a mould cavity. This process is efficient for mass production and allows for the production of containers with intricate designs.

- Blow Moulding: Used for producing hollow plastic containers, such as bottles and jars. In this process, plastic is melted and formed around a mould through the use of pressurized air.

- Glass Blowing: This traditional technique is used for shaping glass containers. A gather of molten glass is blown into a mould, and the glass takes on the shape of the mould.

Design Considerations:

The design of a food container mould takes into account the specific requirements of the food product it will contain. This includes considerations for size, shape, sealing mechanisms, and any special features required for the particular type of food. Emphasis is placed on creating a mould that facilitates easy demoulding and minimizes the risk of contamination.

Food-Grade Standards:

Food container moulds must comply with strict food-grade standards and regulations to ensure the safety of the packaged food. Food Container Mould Manufacturers use Materials in the mould construction should be non-toxic and resistant to chemical reactions that could affect the food.

Hygiene and Cleanability:

Molds used for food containers must be designed with ease of cleaning in mind to maintain hygiene standards. This is particularly important for moulds used in the production of containers for perishable or sensitive food products.

Quality Control:

Rigorous quality control measures are implemented to ensure that the food containers meet safety and quality standards. This may involve inspections for dimensional accuracy, material integrity, and surface finish.

Manufacturers of food container moulds must adhere to industry-specific regulations and standards to guarantee the suitability of the containers for food contact and consumption.