A container mold for biryani would be designed specifically to create containers suitable for packaging biryani, a popular South Asian dish. Biryani Container Mould Manufacturers work on these containers are typically designed to hold a single serving of biryani and are often made of materials such as plastic, aluminum, or biodegradable materials.

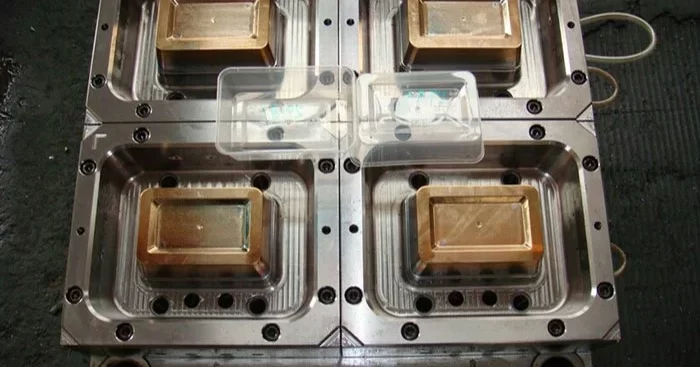

Similar to molds for other types of containers, a mold for biryani containers would be customized to the desired shape, size, and material of the container. Injection molding is a common method for creating plastic containers, where molten plastic is injected into a mold cavity under high pressure and then cooled to solidify into the desired shape.

For aluminum containers, processes like metal stamping or deep drawing may be used. Metal stamping involves pressing a flat sheet of aluminum into the shape of the mold cavity, while deep drawing involves drawing a metal blank into the mold cavity to create the container shape.

In the case of biodegradable materials, molds may be used in processes such as compression molding or thermoforming, where the material is heated and formed into the shape of the mold cavity.

Biryani Container Mould Manufacturers use regardless of the material and manufacturing process used, the mold for biryani containers would need to be designed with considerations for the dimensions of the container, its structural integrity, and any features required for sealing or stacking the containers efficiently.