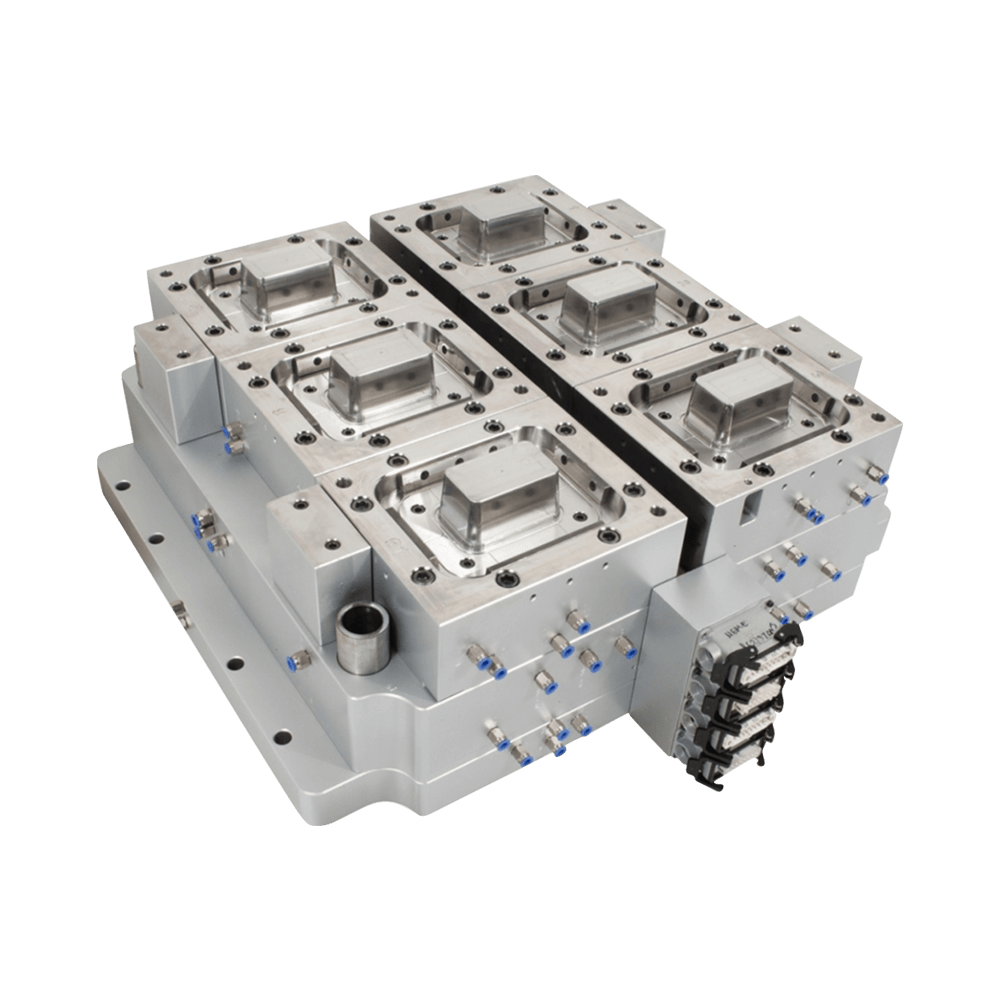

IML Container Mould

In-Mold Labelling (IML) is a variation of the injection moulding process. In IML, a pre-printed label or graphic is placed into the mould before the injection of molten plastic. The plastic then bonds with the label during the moulding process, effectively “embedding” the label into the plastic part for IML container mould. This results in a finished product with a durable, high-quality label or graphic on its surface. IML is often used in the production of items like food containers, cosmetic packaging, and various consumer products.

IML offers several advantages, including: –

Durability: – Labels are protected within the plastic, making them resistant to wear, moisture, and other environmental factors.

Aesthetics: – IML allows for high-quality, full-colour graphics and branding on products.

Efficiency: – The labelling and moulding processes are combined, reducing the need for additional labelling steps.

Cost-effectiveness: – IML can be cost-effective for large production runs.

Design flexibility: – IML can accommodate complex shapes and designs.

Injection Molding Machine Compatibility: – IML container mould needs to be compatible with the specific injection molding machine that will be used for production.

125ml Round Container

- Part Wt. 8 Gms (+/- 1 gms)

- Wall Thickness – 0.5mm (+/- .05mm)

- No. Of Cavity – 8 Cavity

- Cycle Time – 6.5 Second

1000ml Square Container

- Part Wt. 35 Gms (+/- 1 gms)

- Wall Thickness – 0.65mm (+/- .05mm)

- No. Of Cavity – 4 Cavity

- Cycle Time – 8 Second